Advantages:

- Leveraging digital fabrication ensures precise production of small diameter polymer optical waveguides.

- Method seamlessly integrates optical interconnects with electronic circuitry, improving overall efficiency of the system.

- This technology offers flexibility for diverse applications in computing, communication, and beyond.

Summary:

Existing methods for polymer optical waveguide fabrication face constraints in complexity, size, and transmission efficiency. These limitations hinder the creation of compact and efficient optical interconnects, especially for small-diameter waveguides. Integrating optical components with electronic circuitry poses additional challenges due to manufacturing process disparities.

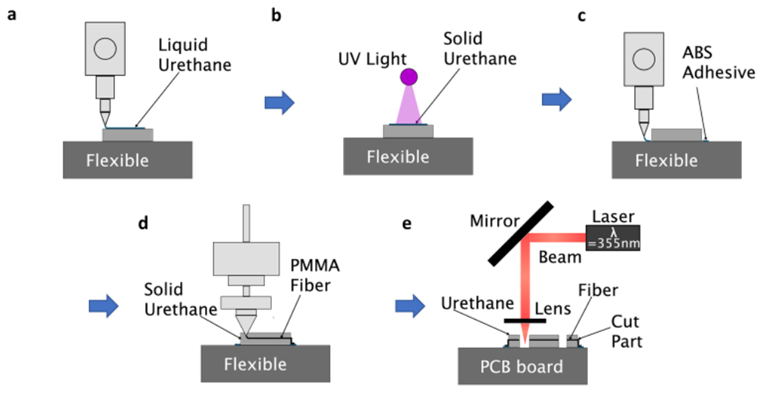

Our technology offers a solution through digital fabrication techniques like micro-dispensed UV optical adhesive, fused deposition modeling, and subtractive laser processes. This method enables precise production of small-diameter polymer optical waveguides with exceptional efficiency. It also allows for direct printing of optical interconnects onto circuit boards, facilitating seamless integration of optical and electronic components. This advancement promises significant strides in computing, communication, and related fields.

A series of images depicting using a composite additive and subtractive LE-DPAM process for producing CCS Optical fiber interconnects on a PCB board.

Desired Partnerships:

- License

- Sponsored Research

- Co-Development