Advantages:

- Improves hydrophobicity and hydrophilicity, optimizing material performance for diverse applications.

- Benefits medical implants, self-cleaning surfaces, and more, offering broad utility across industries.

- Preserves core material characteristics while enhancing surface properties, ensuring stability and reliability.

Summary:

This technology enables precise modification of Polycarbonate (PC) and Polymethyl Methacrylate (PMMA) surfaces using low-pressure plasma treatment and straightforward patterned templates, allowing for the tailored adjustment of surface properties such as hydrophobicity and hydrophilicity. This approach holds significant potential across various domains, including medical implants and self-cleaning surfaces, all while preserving the intrinsic material characteristics. Through sequential multiple plasma gas treatments, substantial improvements in surface wettability have been achieved. This method represents a notable step forward in enhancing material functionality without altering its core properties, with applications spanning drug delivery systems and energy-efficient solutions. In summary, this technology leverages low-pressure plasma treatment and patterned masks to create adaptable PC and PMMA surfaces with customizable properties, promising valuable applications across diverse industries.

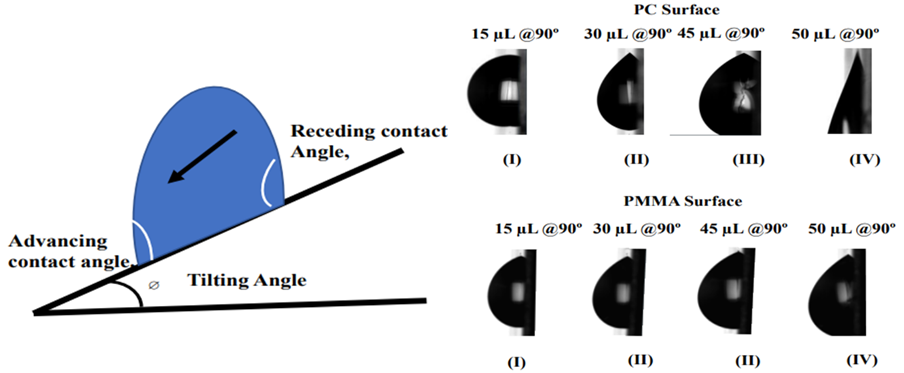

Illustration of advancing, receding, and tilting angle and optical camera pictures of untreated PC and PMMA surfaces with (I) 15 µL (II) 30 µL (III) 45 µL and (IV) 50 µL drop of DI water with 90 degrees tilt angle.

Desired Partnerships:

- License

- Sponsored Research

- Co-Development