Advantages:

- Improved efficiency

- Increased flow rates

- Reduced pressure drops

- Self-adjusting flow conditioning tabs

- Energy savings

Summary:

The market for flow conditioning devices in fluid flow applications to improve flow and energy efficiency, especially heat exchangers, is growing due to increased demand for energy efficiency in industries like HVAC, building air cleaning, power generation, petroleum and gas transportation pipelines, and industrial processes. This revolutionary development of streamlining elements for flow conditioning in systems requiring fluid flow in bends and other annular passages reduces pressure drop and increases flow rates much more than any other flow conditioners on the market. Our flow conditioners make the flow profile more uniform which minimizes pressure drop and increases flow rate thereby saving energy. Our innovation delivers substantial heat transfer enhancements, surpassing traditional methods by up to eight times, join us in optimizing fluid flow and revolutionizing heat exchanger technology for enhanced efficiency across diverse industries.

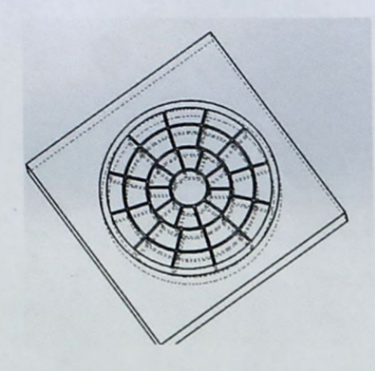

Figure 1. Full plate with annular passages

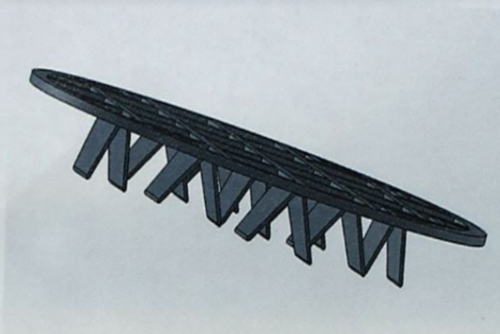

Figure 2. Tab based flow conditioning devices with rigid fixed support

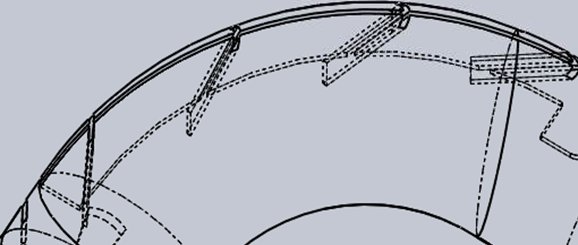

Figure 3. Flow conditioning inside a 90-degree bend.

Desired Partnerships:

- License

- Sponsored Research

- Co-Development