Advantages

- Dual objective optimization

- Scalable performance

- Energy-efficient planning

- Real-time decisions

Summary

Modern smart factories driven by small-batch, customized production face a pressing need for flexible, energy-efficient robot coordination that can adapt instantly to changing demands. Existing Multi-Robot Task Allocation (MRTA) techniques like linear programming, heuristics, or auction models often collapse under dynamic workloads, either sacrificing decision speed or compromising task quality. These limitations obstruct scalable automation and increase energy overhead, threatening operational agility in Industry 4.0 environments.

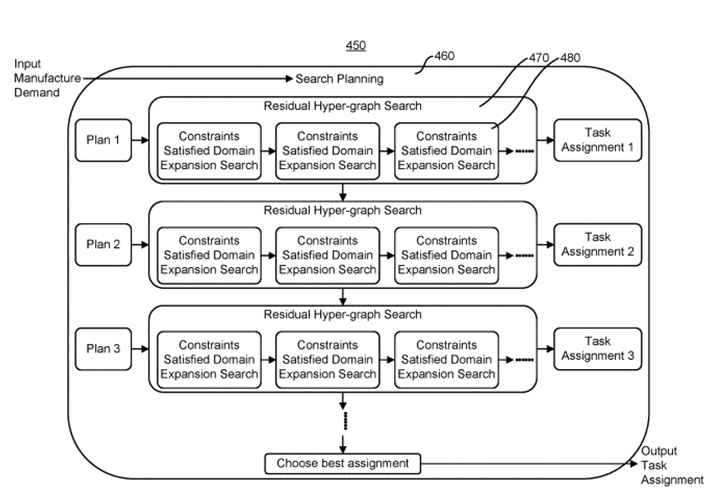

Our patented technology redefines MRTA by modeling robot systems as temporal-spatial hypergraphs capturing each robot’s multitasking capacity and inter-robot transfer energy as weighted relationships. Through a unique three-stage nested search mechanism and statistical marginal-bound estimation, it delivers near-optimal task and transport assignments in milliseconds. Unlike conventional methods, this system adapts in real time with consistent performance even at scale, offering unmatched scheduling resilience, energy-awareness, and computational efficiency.

The three-stage algorithm that enables real-time, energy-efficient multi-robot task assignment through hypergraph search and heuristic evaluation.

Desired Partnerships

- License

- Sponsored Research

- Co-Development