Competitive Advantages

- Provides an economical alternative to fabricate Al alloys and multilayer structures

- Highly scalable compared to other techniques

- Easily control of the composition and phase of deposition

Summary

USF inventors have demonstrated, for the first time, a feasible and cost-effective alternative method to fabricate Al alloys and multilayer structures by electrodeposition in non-aqueous room-temperature ionic liquids. Specifically, they have identified a method of dissolving NiCl2 in 1-Ethyl-3-methyl Imidazolium Chloride/Aluminum Chloride electrolyte to provide good conductivity, low vapor pressure, and a wide electrochemical window; all of which are limited in current conventional practices.

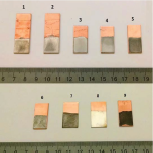

Different Parameters Deposited to Study the Effect of Deposition Potentials, Duty Ratios, and Frequencies on Alloy Composition

Desired Partnerships

- License

- Sponsored Research

- Co-Development